| A PURSUIT IN TURBULENCE: THE TRACEABILITY SYSTEM AS THE BASIS FOR CONSUMER ASSURANCE

Safety comes first. What is the purpose of a food company’s existence, if consumers have to worry about the food they put into their mouths every day? As one of the largest chicken meat suppliers in China, Dachan never forgets its mission, and has been involved in providing consumers with safe and quality food and advocating a healthy modern lifestyle. To guarantee and communicate this objective, Dachan Food has been striving to establish a food traceability system since 2006, which has comprehensively standardized its application in its whole supply chain since 2009.

TRACEABLE = ASSURED?

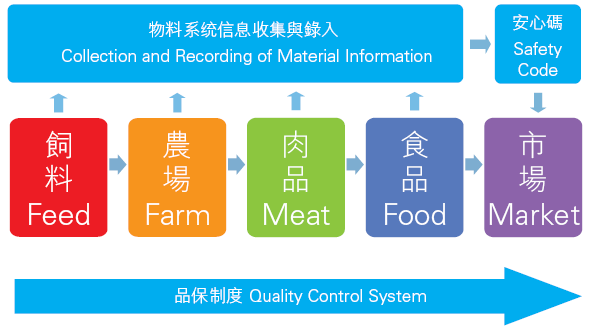

The food safety traceability system was firstly established in 1997 in the EU in response to the “mad cow disease” incident and then gradually improved. In modern times, food is complicated in its production, processing, ingredients, and distribution. Safety issues may appear at any of the above stages. The traceability system covers both the upper and lower parts of the whole supply chain including feed production, breeding and rearing, meat production, food processing, and distribution. It monitors goods quality and serves end-consumers through a specialized system. Consumers of Dachan Food can investigate online through the use of the “Safety Code” on product labels to obtain information about the production plant, the farms and key test results. The company insists on information transparency, which enables consumers to be confident in the food and actively monitor food safety if necessary. When food quality issues do appear at the consumer end, it enables sources of such issues be found out instantly. This system is significant to food safety and the self-discipline of the food industry, and has been adopted in over 40 countries, with the most effective examples in England, Japan, France, the US and Australia. Dachan’s highly integrated supply chain and advanced information platform makes it possible for food traceability to be realized in China.

「100–1=0」

In 2012, under increasing challenge of the breeding and rearing environment, the Group launched the campaign of “General Mobilisation of 100% Assurance” to achieve the goal that food companies must pursue 100% product safety. “For consumers, one unqualified product in 100 products means 100% unqualified. It is 100–1=0, not 100–1=99.” The “fast grown chicken incident” that broke out at the end of the year demonstrated that food companies should not have a wishful thinking that food safety issues will not be uncovered. In the campaign, the Quality Control Centre implemented “Five Unifications” system, under which control processes of each department were refined. Self-inspection was conducted by each operating department to examine the production stages which are prone to safety risk, and to strictly monitor these key segments of productions, to identify and resolve problems, enhance production quality, and create an environment for production without drug residue, foreign objects and degradation. The“Five Unifications” system, which is the core system of the centre, is an important quality control principle of contract farming now commonly used worldwide. It unifies day-old chick supply, material supply, disease prevention, drug prescription and slaughter, and requires companies to unify the supply and management of the contract farmers in relation to day- old chicks, feed, rearing and feeding process, disease prevention and pre-slaughter inspection to ensure chicken quality in the entire production chain.

FEED

FEED SUPPLY

Under Dachan’s traceability system, feed for broilers are manufactured and provided to contract farmers by Dachan to ensure standardized feed consumption. This part establishes control and traceability of feed from manufacture, quality inspection, to usage, and is the start and premise of Dachan’s traceability system.

INFORMATION CONTAINED IN THE SAFETY CODE

• Record of Feed Release

• Hygiene standards

• Information about the plant director

• Information about the quality control officer

• Food safety system certification

• Details of Feed Release

INSPECTION STANDARDS

• Hygiene standards – National Feed Hygiene Standards GB 13078-2001

• Additives – National Feed Additive Safety Use Notice No.1224

• Drug additives – in compliance with the Ministry of Agriculture No. 168 “Use of medicated feed additives”

QUALITY CONTROL MEASURES

• Unified provision of qualified feed from feed factories of the Company to breeders and strict supervision over the rearing and feeding process

• The placement of additional technician at every feed factory to take charge of rearing inspection, provide instruction on rearing and communicate with feed factories.

• Control over cross-contamination in the production process ensuring the absence of drug residue

FARMS

REARING

Contract farmers are important suppliers to Dachan Group. Therefore, the tracing and supervision of daily rearing performance of the farms, as well as pre-slaughter inspection of chicken in the Traceability System directly relate to meat quality and is the most important control point for drug residue.

INFORMATION CONTAINED IN THE SAFETY CODE

INFORMATION CONTAINED IN THE SAFETY CODE

• Length of cooperation with Dachan

• Location of farms

• Time and volume of release

• Information about the quality control officer and farm veterinarian

INSPECTION STANDARDS

• Pre-slaughter inspection: inspection for drug residue under national standards

QUALITY CONTROL MEASURES

• Unified day-old chick supply: unified provision of certified day-old chicks by hatcheries of the Company to farmers

• Unified disease prevention: According to the biohazard principles for farms, the Group’s Animal Health Department works out immunization programs and the Company unifies the plan and execution for vaccine usage

• Unified drug usage: unified procurement of qualified drugs, supervision of all dosage records and tracking of effects and ending time

• Periodic inspection by representatives and reporting of the rearing process strictly in line with rearing manual

• Sampling at farms by designated staff on all chicken sources 3-5 days prior to slaughtering to exclude unqualified birds from being processed MEAT

MEAT

SLAUGHTER

The part of the traceability system occurs after the farmer sends his birds for slaughter. It supplements the pre-slaughter testing to provide double assurance for the safety and quality of the meat.

INFORMATION CONTAINED IN THE SAFETY CODE

• Date of manufacture

• Test results of antibiotics residue

• Test results of melamine residue

• Information about the slaughterhouse manager

• Information about the quality control officer

• Food safety system certification

INSPECTION STANDARDS

• Food safety system certification-ISO9001 quality management system certification; HACCP food safety management system authentication; and ISO22000 food safety management system certification.

• Department of Agriculture, 235 GB16869-2005 and related laws and regulations

QUALITY CONTROL MEASURES

• Unified slaughter: unified arrangement for transportation and post-slaughter tests

• Post-slaughter tests: a second test performed by sampling birds on the production line after entering the slaughterhouse FOOD

FOOD

PROCESSING

This part is about control and tracing of food processing, packaging and entering end consumer market. Quality control information from all segments are integrated and generated here when consumers see the “Safety Code” on packages of “Sisters’ Kitchen” products.

DETAILS OF THE SAFETY CODE

• Date of manufacture

• Results of sensory tests

• Results of microbe tests

• Information about the processing plant manager

• Information about the quality control officer

INSPECTION STANDARDS

• JJF 1070-2005 “Fixed Volume Prepackaged Goods Measurement and Inspection Provisions”

• SB/T 10379-2004 Frozen Prepared Foods

• Food safety system certification-ISO9001 quality management system certification; HACCP food safety management system authentication; ISO22000 food safety management system certification.

QUALITY CONTROL MEASURES

• Establishment of supplier management system, under which strict evaluation is conducted on materials and packaging suppliers for selection to ensure safety of raw materials

• Comprehensive control over the whole manufacturing process by the Quality Control Centre, under which ingredients, external procurement, automatic processing lines, product packaging and warehousing are all standardized

• Inspection at production line of every physical and chemical indicators, for every product batch to ensure safe processing, and thus food safety and quality

REVIEW

IN THE PAST YEAR, WE ACCOMPLISHED THE FOLLOWINGS:

Quality improvement activity “General Mobilization on 100% Assurance: 100 – 1 = 0” Identifying potential problems and improving regulations and systems

• Insisting on the quality goal of zero drug residue, foreign objects and degradation

• Serving customers and enhance their satisfaction

Drug residue control

• Promoting pre-slaughter drug residue test on chicken in minimizing risk of drug residue, along with post-slaughter test to give double assurance

• Developing new drug residue examination technology to improve capability, expanding test items and establishing test centres of advanced standards

• Paying attention to developments in the food industry, analyzing food safety risks and taking precautionary measures in advance

• Adapting to diversified development of products of the Company and expanding the scope of application of the Traceability System ranging from broiler to pork, native chicken and other variety

Marketing

In food safety and traceability, Dachan has made great leading progress and will continue to put more effort in the future. We sincerely hope our consumers will recognize these efforts and enjoy the safety of the food when purchasing Dachan products. We will search for better ways to communicate with consumers and express our values at every opporutnity.

• Optimization of the traceability program on the official website of “Sisters’ Kitchen”

• “Sisters’ Kitchen” official Weibo

• Distributors’ convention

• Retail in over 500 stores and supermarkets

IN THE FUTURE, WE WILL ALSO…

• Introduce the most advanced equipment and technology into the Group’s test centre to elevate the Group’s standards to a higher level

• Forge closer relationships among information teams by comprehensively digitizing and systematizing quality control data through advanced technology

• Strengthen quality control at all segments of the highly integrated business mode of the Group, for instance, supplier management, educating farms and farmers about traceability and food safety and communication with end-consumers

• Continuously strengthen quality control skills and awareness of primary staff

|